Fire Pump Tests

Fire Pump Testing (NFPA25 and NFPA20)

NFPA 25

currently requires annual performance testing of fire pumps. In a performance

test water is discharged and the net performance of the fire pump is analyzed

through a minimum of three flow points. NFPA 25 also requires non-flow testing

of fire pumps, were the fire pump is started and run for a time interval under

churn conditions. Currently weekly non-flow tests are required for diesel fire

pumps and monthly non-flow tests are required for electric fire pumps. The

non-flow test frequency remains an item that is debated during every NFPA 25

code cycle. NFPA 25 contains the testing requirements after acceptance. Two

different types of fire pump test are required: Performance Tests, and Non-flow

tests. In the 2007 edition of NFPA 25 Non-flow fire pump tests were required

weekly for both electric motor and diesel engine drive fire pumps. In the 2011

edition of NFPA 25, the required test frequency for electric motor drive fire

pumps was reduced to monthly. NFPA 20

contains the requirements for acceptance testing of fire pumps.

NON-FLOW TESTS

Although

NFPA 25 requires qualified personnel present at all pump tests, non-flow test

can be conducted automatically by new fire pump controllers. If the pump starts

automatically from a pressure drop, and completes the required run cycle, it

would pass, even if no one was there to observe the pump performance.

Non Flow

tests are required primarily to verify if the pump will start and run without

any apparent problems. Data for these tests can be on a paper check list and

require visual observation but no analysis. The data collected could be limited

to the date tested, or there might be a list of items that were visually

inspected. In a non-flow test the pump operates at churn for a minimum time of

10 minutes for electric motor pumps and 30 minutes for diesel engine fire

pumps.

The only

water discharged is a small quantity through the circulation relief valve in order

to keep the pump from overheating. NFPA 25 currently requires non-flow test to

be conducted weekly for diesel engine fire pumps and monthly for electric motor

fire pumps

PERFORMANCE TESTS

The

annual fire pump performance test is also an opportunity to determine if there

are any problems with the fire pump water supply, such as shut or partially

shut valves or obstructions from the water supply to the pump. If the test is

conducted with a flow meter, it usually will not be possible to identify

problems with the fire pump water supply NFPA 20

requires a performance test before pump acceptance.

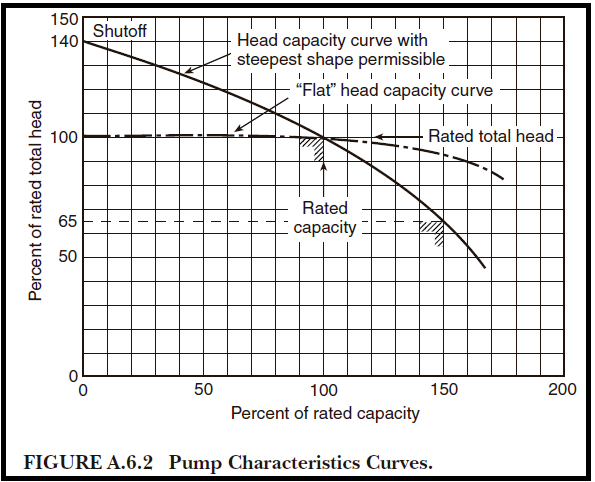

NFPA 25

requires a yearly performance test in which performance readings are recorded

at Churn pressure - no flow, 100% of rated flow, and 150% of rated flow. Annual

flow testing is typically performed by qualified personnel who have a better

understanding of the fire pump operation.

Acceptable

test results can be up to 5% below the above figures due to possible

experimental error. Test results worse than 5% below the next figures (by NFPA20) should be

investigated and corrected.

FIELD ACCEPTANCE TESTS PROCEDURE

This activity

evaluates the pump performance over a range condition to ensure the pump will

perform as needed during an any emergency.

First, make

a visual check of the fire pump package. Verify the proper setting of pressure

switches and circuit breakers. Check for signs of overheating and excessive vibration. If hose and nozzles are

used, ensure they

are securely tied down. Ensure the hose valves are closed. If a flow meter is

used, verify the valve on

the discharge side of the meter is closed. Verify the pressure in the mains is

normal (i.e., jockey pump pressure)

to prevent water hammer.

After

starting the pump, verify that the relief valve (if provided) is not flowing

water, and then partially open one or two hose valves, or slightly open the

meter discharge valve. Check the general operation of the pump and driver.

Watch for vibration, leaks (oil or water), unusual noises, and general

operation; confirm slight water flow from packing glands.

If

a test valve header is used, regulate the discharge by means of the hose valves

and selection of

the nozzle tips. The play pipe has a removable 1 1⁄8-in. (28.6 mm) tip and,

when the tip is removed, the

play pipe has a 1 3⁄4-in. (44.4 mm) nozzle.

When a test meter is used, regulate the discharge valve to achieve

various flow readings

Test

the fire pump over its entire range of flow (0 to 150% of the rated capacity)

by controlling the quantity of water discharged. Start at low flow and

gradually increase it; starting the pump with hoses open

can cause cavitation. Important test points are at churn (no flow), rated

capacity, and 150% of rated

capacity. Two intermediate points should be taken to help develop the

performance curve.

Record

the following data at each test point: (a) Pump rpm (b) Suction pressure (c) Discharge pressure (d) Number and size of hose nozzles, pitot

pressure for each nozzle, and total gpm (L/min). For flow meter, record gpm

(L/min) (e) Amperes and volts (for electric motors drivers)

Analyze the data with the pump manufacturer submittal.

Throughout

the course of testing, start the pump 6 times manually and 6 times

automatically to verify prompt and smooth start-up at the required

pressures or flow. For electric motors, allow at least 5 minutes at full speed

after each start-up to allow motor windings to cool properly. For

electric motors > 200hp (150kW), no more than 2 starts in 10 to 12 hours

should be attempted, and a running interval of at least 15 minutes at full

speed should be allowed.

For

a diesel engine run the pump for at least 1 hour to verify smooth operation

without coupling failure or overheating. Check this by discharging at the 150%

point, allowing the engine temperature to stabilize,

and then run the pump for an additional 15 minutes.

After

the test, verify pressure in fire service mains is up to normal or up to jockey

pump pressure before the pump is returned to automatic service to prevent water

hammer. Verify all fire protection equipment is returned to the automatic mode

and fire protection control valves fully open. Only the valve to the test

header should remain closed

Comments

Post a Comment